HACCP Food Safe Flooring for Brewery, Winery, bakery, Dairy & Meat Processing Industries

Specialised Resinous Systems for the Food & Beverage Industry in Australia

At Epoxy Flooring Tech, we deliver fully integrated food-grade flooring and coating systems designed to meet the rigorous hygiene, chemical, and thermal demands of the food processing and hospitality sectors. From importing raw materials to final certification, we control the full lifecycle of your flooring system—formulation, supply, installation, and long-term maintenance.

As a professional applicator of high-performance epoxy and PU cement floorings, we provide project-specific flooring systems—with durability, hygiene, and compliance with HACCP, FSANZ, and AS/NZS standards in mind. Whether it’s a new epoxy floor for commercial kitchen, a high-throughput winery, or a -40°C freezer, our tailored solutions ensure operational continuity and safety.

Comprehensive End-to-End Service

Our offering extends well beyond installation:

-

Certified Installation – installed by trained applicators under strict protocols

-

Ongoing Maintenance – discounted service packages designed to maximise flooring lifespan

-

Audit & Certification Support – assistance with final inspections and compliance documentation

We proudly serve a broad spectrum of industries across Australia and the Pacific, including wineries, breweries, food processors, aged care kitchens, dairy facilities, abattoirs, and chemical storage areas.

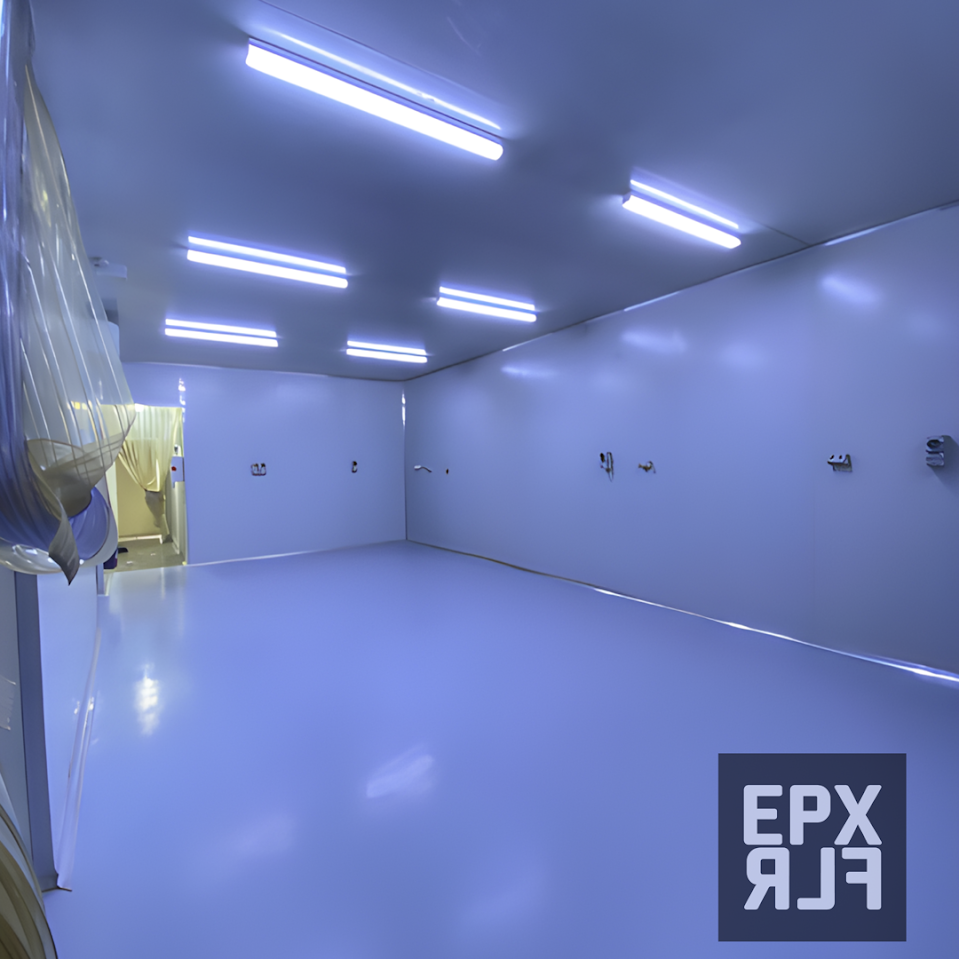

Chemical-resistant Novalac epoxy floor, Western Sydney.

Seamless, Hygienic, and Certified: Food-Grade Flooring Systems

Our wall-to-floor integrated epoxy and polyurethane (PU) systems offer:

- Seamless, impermeable finishes – eliminate bacterial harborage points

- Chemical resistance – withstands acids, alkalis, fats, oils, and ethanol

- Non-slip surfaces – ensures safe pedestrian and trolley traffic

- Thermal shock tolerance – ideal for areas with extreme temperature cycling

-

Mechanical durability – resists abrasion, impact, and heavy trolley loads

-

Rapid cure options – tailored for overnight refurbishments with minimal downtime

-

Colour stability & design flexibility – multiple colour options for zoning and aesthetics

All systems comply with food safety regulations and are proven performers in environments requiring frequent washdowns, hot water exposure, and high footfall.

Typical Application Environments

- Commercial Kitchens

- Cool Rooms & Freezers (0°C to -40°C)

- Wineries & Breweries

- Food & Beverage Processing Lines

- Wash Bays, Loading Docks, Storage Zones

- Hospitality, Aged-Care & Institutional Kitchens

1. Food-Grade Epoxy Flooring for Light Chemicals & Organic Spills

In facilities where diluted acids, alkalis, detergents, and organic matter are routinely present, conventional coatings often fail. Our food-grade coatings are designed to handle:

- Acetic acid, citric acid, sodium bicarbonate, ethanol, and food oils

- Daily exposure to hot water washdowns and alkaline detergents

- Impact from stainless or steel-wheeled trolleys

- Penetration risks from organic food spills and sugar residues

2. Chemical-Resistant Food Grade Flooring for Harsh Environments

Certain sectors demand flooring that withstands aggressive chemicals while maintaining food safety compliance—notably in dairies, abattoirs, and chemical-processing food plants.

Common exposure chemicals:

- Hydrochloric Acid (HCl)

- Nitric Acid (HNO₃)

- Sulphuric Acid (H₂SO₄)

- Sodium Hydroxide (NaOH)

- Acetic Acid (>10%)

- Peracetic Acid & Disinfectants

Our high-performance novolac and chemically resistant epoxy systems include:

- Novolac Epoxy

Engineered for high chemical resistance and food-safe certification. - Low Viscosity Food-Grade Epoxy

Formulated for penetration into porous surfaces and chemical immersion zones.

Typical chemical-intensive clients:

- Dairy processors using Nitric Acid Clean-in-Place (CIP)

- Vinegar manufacturing plants

- Meat & poultry abattoirs

- Beverage and ethanol processing facilities

Fast-Cure Systems for Overnight Installations

Where operational continuity is critical, we offer fast-track curing systems that dramatically reduce downtime.

Epoxy Mortar System

- Two-hour open time, yet recoat able in four hours

- 100% solids binder mixed with high-density dry quartz (100μm–5mm)

- Used for high-build applications including epoxy screeds and trowel-down mortars

Ideal for:

- Overnight kitchen refurbishments

- Weekend shutdowns in production facilities

- Rapid repairs in cold storage environments

Flexible Flooring Systems with Shock Absorption

Flexibility is vital in areas subject to mechanical shock and thermal movement. Our elastomer-modified food-grade epoxies are designed to:

- Absorb impact from dropped tools and machinery

- Withstand structural movement or thermal expansion

- Maintain adhesion and integrity over uneven or shifting substrates

Optional Add-ons & Certifications

- Non-slip textures (R10–R13) based on area classification

-

Anti-microbial additives

- Certifications support: HACCP, FSANZ, TGA, USDA-equivalent

- UV-resistant topcoats for exposed or semi-external zones

- Coloured quartz or flake systems for visual appeal or zone demarcation

Summary of Key Features

| Feature | Description |

|---|---|

| Food-Grade Compliant | Suitable for direct and indirect food contact |

| Seamless Wall-to-Floor Integration | Easy to clean, no bacterial traps |

| Fast Curing Options | Overnight installs with minimal downtime |

| Chemical Resistance | Withstands strong acids, alkalis, fats, ethanol |

| Extreme Cold Performance | Rated for -40°C freezer environments |

| Flexible Formulations | Withstand impact, vibration, and thermal shock |

| Low VOC & Solvent-Free | Safe for occupied environments |

| Custom Colours & Textures | Match your operational or branding needs |

For technical consultations, custom formulation advice, or compliance documentation support, contact Epoxy Flooring Tech today. We’re Sydney-based, HACCP-aware, and ready to help you achieve food safety compliance without compromising performance.